Thermal energy conservation systems are not new to the market. These batteries take advantage of temperature changes to be able to store energy for later use, either at the capture site or elsewhere.

The method used for the longest time, and associated with its high energy density, takes advantage of the amount of heat energy needed to change a physical state (from solid to liquid or from liquid to gas, for example) but without modifying the temperature of the materials.

The latest ones still use thermal energy, but this time to increase the temperature of a substance, without causing any change in its physical state.

The latter technique is more advantageous in terms of costs, which are lower.

Lehigh Thermal Battery: The best of both worlds

Now, a team of engineers from Lehigh Universityin Pennsylvania, USA, dissatisfied with both existing technologies, decided to develop a new thermal power system that utilized the best that each of the above methods could offer.

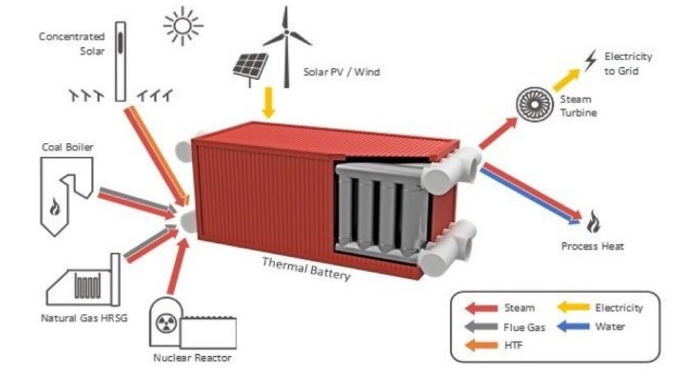

With support from the US Department of Defense, this team then created the Lehigh Thermal Battery, which uses cementitious materials and a thermosiphon, in a union that results in fast, efficient, and at the same time economically efficient thermal performance.

This battery is able to operate with both heat and electricity in terms of energy input for charging.

After three years of research and development, the responsible team announced that Lehigh’s thermal battery is ready for sale to the public..

One of the prototypes, with a power of 150 kW, is fully functional and has 22 thermal fins.

Extensive testing carried out using compressed air at a temperature of 480°C, resulted in a charge and discharge efficiency of 95%, while the temperature remained evenly distributed during charging in all cycles.

The average power rate achieved while charging was 16.4 kW, and while discharging was 19.8 kW, with a very fast thermal battery energy gradient during the first hour of discharge: 0.51 kWh/min.

Sudhakar Neti, Professor Emeritus at Lehigh, points out that this technology is innovative in several ways:

“They are modular, designed for independent input/output power flows during charging/discharging, which is possible with the help of a thermosiphon. The two-phase changeover process within the thermocouple heat pipes allows for rapid even heat transfer from/to storage media at very high heat transfer coefficients and heat rates.” .

Lehigh’s thermal battery properties make it potentially able to help accelerate the decarbonization of polluting industrial sectors with high energy needs, while enhancing the penetration of concentrated solar power.

Video – What is a thermosiphon?

“Wannabe internet buff. Future teen idol. Hardcore zombie guru. Gamer. Avid creator. Entrepreneur. Bacon ninja.”